Nitin Bajpai, Raghav Pachouri, Vrinda Gupta

For the past two to three decades, the fashion industry has come under the spotlight for causing negative impacts on the environment and society at a global level. This is because the decrease in the price of apparel and faster trend cycles have resulted in increased consumption of clothes globally. As per UNFCCC, the fashion industry is responsible for 10 percent of anthropogenic carbon emissions surpassing the emissions generated from aviation and shipping industries.[1] It has been projected that if the fashion sector continues on its current trajectory, the share of the carbon budget will jump to 26 percent by 2050[2].

Fast Fashion: Consumers today are buying 60 percent more clothing items than they did in 2000, but they are also keeping each garment for only half as long.[3] The latest business model is exacerbating climate change consequences from the mass scale of production but also through clothing and textile waste generation.Around 100 billion new garments are manufactured each year, producing a total waste of 92 MT each year out of which 42 MT is plastic waste, which is created from the use of synthetic-based raw material such as polyester. Out of the total waste generated, 87 percent end up in landfill while only 1 percent is recycled. As clothing degrades in landfills, it emits methane, a potent greenhouse gas that is 28 times more effective at trapping heat in the atmosphere than carbon dioxide. However, due to limited information and awareness, the consumer is oblivious to all these impacts.

Textile Value Chain

Apparel is one of the most common and frequent products a consumer purchases without being aware of its environmental impacts. Right from the raw material (fibre) to the finished product (apparel), the processes involved consume energy, generate emissions, and create water footprints.

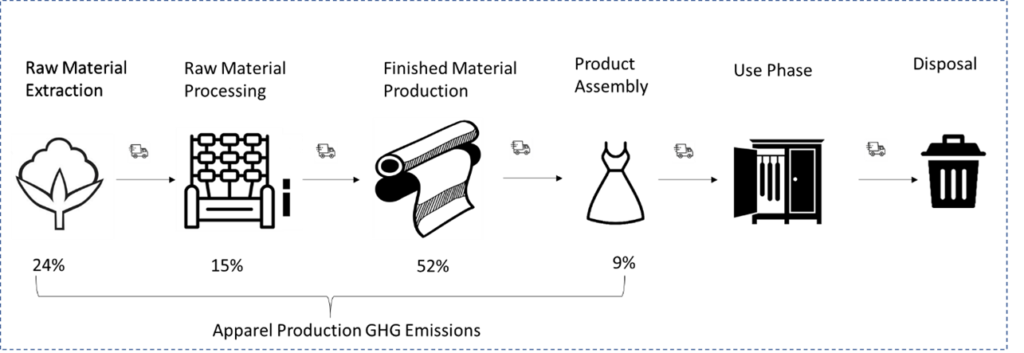

GHG Data Source: WRI, 2021

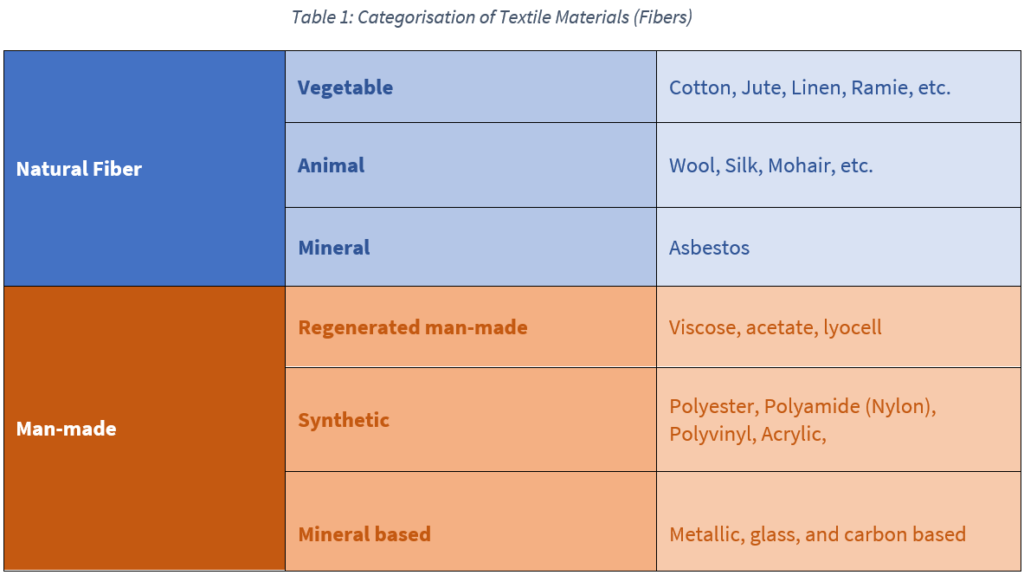

The textile industry has one of the most complex industrial chains in manufacturing, since the raw material used have to undergo the numerous processes based on design and the requirements. Moreover, the number of technologies to perform these processes also varies depending on the origin of the materials (characterised in Table 1 below).

The textile or apparel industry is not just about producing fabrics and apparel but involves a long-chain of traceable processes. The textile value chain for apparel production can be broadly categorised under five broad stages that every material must undergo.

The textile value chain starts with raw material extraction and preparation of fibre, which requires land for vegetative fibres, water, chemicals, hot air, heat, energy, and machinery. It is followed by the spinning process, which is a thread-to-yarn process, and consumes mainly oil, lubricants, water and machinery. Next in the chain comes fabric production (weaving and knitting), which consumes oil, machinery, water and hot sizing liquor. The penultimate process involves the finishing of fabric which includes processes like scouring, bleaching, mercerization, etc., that utilises chemicals, dyes, auxiliaries, machinery, water and heat. As part of these processes, bleaches and dyes are consumed which are chemically laden and environmentally degrading. On the other hand, the dyeing process used for colouring the clothes requires constant washing, which consumes significant amounts of water. The final stage is assembly, that is, cutting and stitching, which needs machinery and energy. Additional processes like printing, embroidery, etc. are subject to design requirements and should be taken into consideration while analysing the impacts of textile products.

Further, the textile processes are carried out in different factories across different parts of the world, involving transportation at each stage, which has significant environmental implications as a result of the huge amount of fuel being used for traction of shipping containers.

Extended Value Chain

The after-sales activities include the use phase and the disposal of garments which largely depend on consumer behaviour. During the use phase, chemicals (such as detergents), energy and water are consumed for washing clothes followed by ironing, for which the local vendors in India still relies on charcoal that has significant environmental impacts. In addition, with limited awareness of the ecological impacts, the laundry cycles in Indian households are quite frequent. Disposal practices in India, although informal, are already sustainable in a sense due to the inbuilt Indian culture of donating, repurposing or giving away garments instead of discarding them.

Comparing the Impacts of Cotton v/s Polyester Shirt

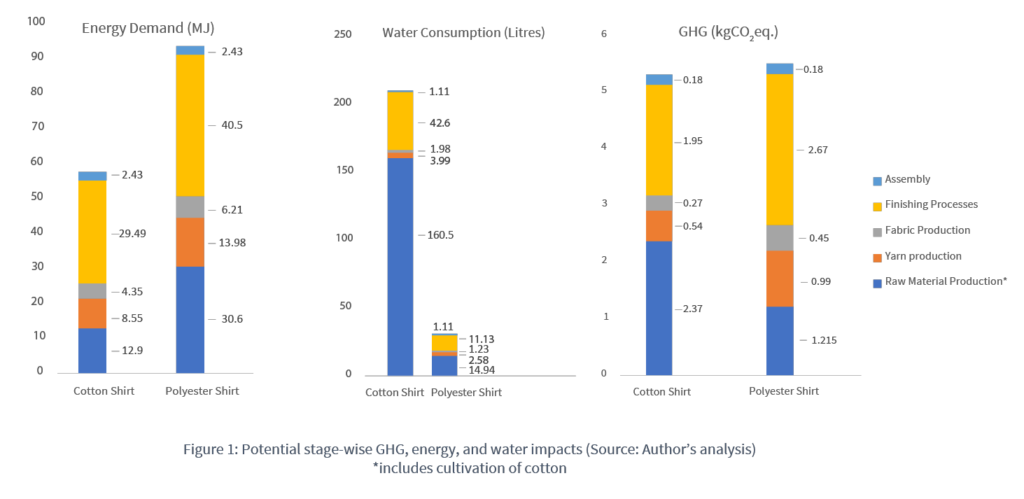

Globally, Polyester (52%) and Cotton (24%) are the two most commonly used raw materials to manufacture fashion products, and their production has a considerable ecological impact.

As already discussed in previous section, a simple garment manufacturing involves a variety of processes that create several environmental impacts. In order to understand these impacts, an example of a cotton and a polyester shirt is taken. A shirt, typically weighing around 300 grams, is selected as a functional unit for the analysis to compare the impacts. The Life Cycle Assessment (LCA) upstream datasets from the ecoinvent[4] (LCA data aggregator) and literature studies have been used to model the impacts of the shirt.

While the impacts shouldn’t be directly compared as the products may have different functionalities, the above analysis is intended to have a better understanding of the impacts associated with different processes for the two most commonly used raw materials in the industry. As can be seen that cotton shirts require large amount of water, while polyester shirts have high GHG impacts and energy demand. The water requirements for cotton can be associated with the cultivation process of cotton and the reactive dyeing process. In contrast, the energy and GHG impacts of polyester are attributed to two processes: melt spinning and disperse dyeing, both of which have high energy requirements usually thermal energy that is fuelled by non-fossil sources.

Sustainable Alternatives

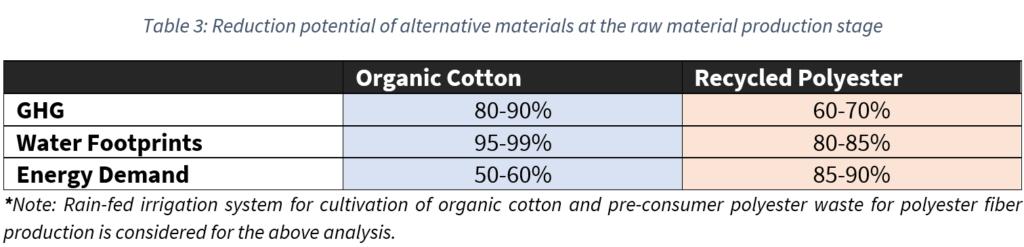

In recent years, brands have been adopting sustainable and alternative materials, such as organic cotton and recycled polyester, respectively, as a substitute to conventional materials, thereby offering a reduction potential for each of the impacts discussed previously. While the rest of the processes have more or less similar impacts for both conventional and sustainable materials, as for the raw material stage the savings potential is listed below. The alternative processes can also be applied to the dyeing process, which is the key hotpot throughout the value chain. The dope dyeing method for polyester is identified as an alternative dyeing method that requires relatively less energy and water.

Way Ahead

India is the world’s second-largest producer of textiles and garments, contributing 2.3 percent to country’s GDP and 12 percent to total exports, while housing 45 million employees, which is the second largest after agriculture. The sector has shown a strong growth over the years, growing at a CAGR of 10.23 percent from 2016, standing at USD 23 billion in 2021. Currently, the textile industry relies heavily on emission-intensive solid fuels for thermal energy requirements in production facilities. Considering the sector’s anticipated growth, an increase in environmental impacts is imperative.

There exists a pressing need to adopt green ways of production including the use of efficient technology, electrification of thermal processes, and transitioning to clean fuels to reduce the associated environmental impacts, combined with the introduction of circular business models like re-commerce and repair, to tackle waste generation.

This blog is a part of the Vasudha Foundation’s Deep electrification initiative.

References

[1] https://unfccc.int/news/un-helps-fashion-industry-shift-to-low-carbon

[2] https://ellenmacarthurfoundation.org/assets/downloads/publications/A-New-Textiles-Economy_Summary-% of-Findings_Updated_1-12-17.pdf

[3] https://www.mckinsey.com/capabilities/sustainability/our-insights/style-thats-sustainable-a-new-fast-fashion-formula

[4] https://ecoinvent.org/the-ecoinvent-database/#:~:text=ecoinvent%20datasets%20contain%20information%20on,products%2C%20co%2Dproducts%20and%20wastes