- Jaideep Saraswat and Nikhil Mall

Solar Photovoltaic (PV) technology has emerged as the optimal solution to combat the climate crisis plaguing humanity. The discovery of the photovoltaic effect by French physicist Alexandre-Edmond Becquerel in 1839 marked the beginning of a journey during which numerous scientists and organisations contributed to its development. In the past decade, solar PV technology has emerged as the optimal solution for generating renewable electricity. Recognising its potential, governments worldwide have implemented favorable policies, regulations, and ambitious targets, enabling economies of scale and propelling solar PV technology to become one of the most cost-effective means of electricity generation in the modern era.

In this article, we examine the data from the National Renewable Energy Laboratory (NREL) which tracks the advancements in photovoltaics starting from 1976[1]. The dataset comprises information from accredited laboratories worldwide, where diverse solar cells were tested under the standardised conditions of 1000 W/m2, AM1.5, and 25°C, known as the Standard Test Conditions (STCs).

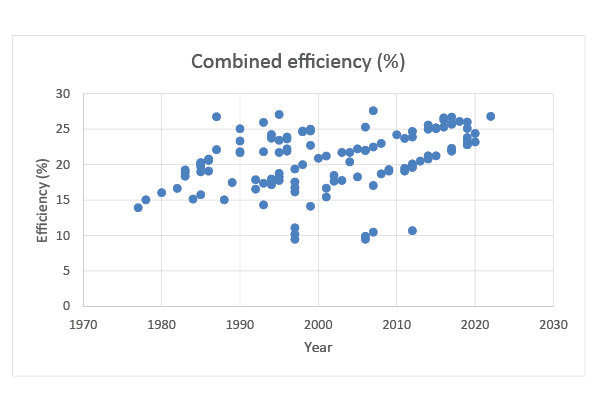

Currently, solar PV technology can be broadly classified into three generations based on its design, materials, and efficiency. First-generation solar PV technologies, also known as ‘traditional’ or ‘conventional’ solar cells, are based on crystalline silicon (c-Si) technology. They dominate the current market and are made of single-crystal silicon or multi-crystalline silicon. These panels have a high-efficiency rate and a long lifespan. Figure 1 illustrates the progression of efficiency in crystalline single junction solar cells spanning from 1976 to 2022. The steady rise in efficiency can be attributed to advancements in materials, manufacturing technology, and the implementation of layered structures. Throughout this period, the efficiency of crystalline solar cells from various organisations has surpassed the 26 percent mark on at least eight occasions, with five of those occurrences taking place within the last decade.

Figure 1: Crystalline Silicon Solar Cell Efficiency Evolution

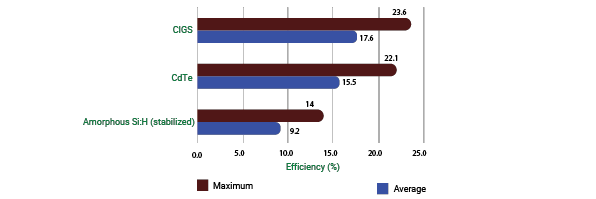

Second-generation solar PV technologies are often referred to as ‘thin-film’ solar cells. These cells use different semiconductor materials, such as amorphous silicon (a-Si), cadmium telluride (CdTe), or copper indium gallium selenide (CIGS). However, they generally have lower efficiency rates. Nevertheless, thin film modules offer the advantages of lower manufacturing costs and reduced weight. As previously stated, these modules tend to have lower efficiency compared to crystalline counterparts. However, Figure 2 clearly demonstrates that the CIGS concentrator has the capability to achieve efficiency levels comparable to crystalline cells.

Figure 2: Efficiency Levels of Thin Film Solar Cells

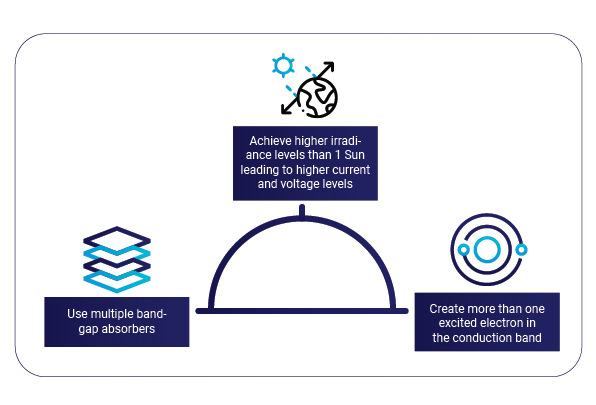

Third-generation PV technologies refer to the approaches that aim to overcome the Schockley-Queisser (SQ) Limit of single bandgap solar cells or aim to reduce the manufacturing cost of solar cells using novel materials and processes. The SQ limit can be breached in three ways as mentioned in Figure 3.

Figure 3: Approaches to Surpass SQ Limit

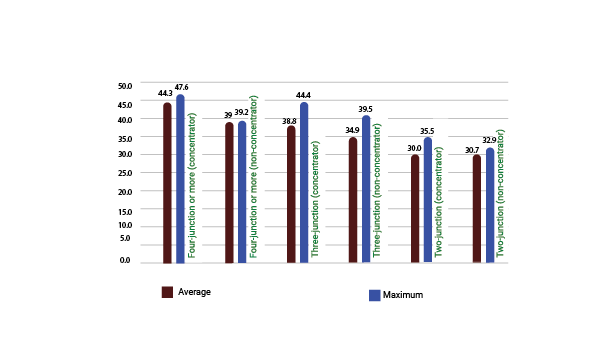

Some of the technologies that can achieve this are multijunction solar cells, concentrator PV, spectral up and down conversion, multi-exciton generation, intermediate band solar cells, and hot carrier solar cells. Figure 4 depicts the mean efficiency of multijunction solar cells. Notably, four-junction solar cells, when combined with concentrator technology, exhibit an average efficiency of 44.3 percent. The most notable advancement in this category occurred recently in 2023, reaching a remarkable efficiency of 47.6 percent. It is crucial to emphasise that, with the exception of multijunction and concentrator technologies, the other mentioned technologies are still in their early stages of development and have not yet achieved high efficiencies.

Figure 4: Efficiency-levels of Multijunction Solar Cells across Different Years

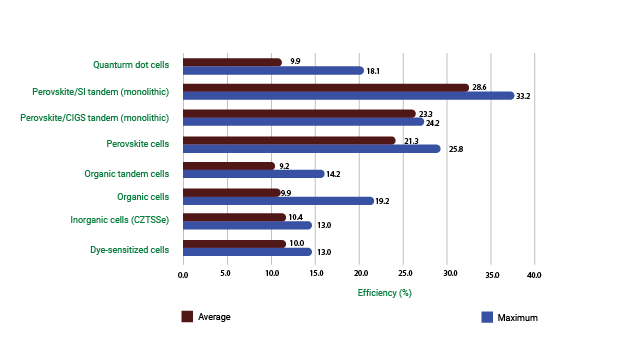

There is a balanced emphasis on advancing technologies that offer cost-effective production, utilise abundant natural resources, and possess lightweight properties. This category encompasses Dye-sensitized solar cells, organic solar cells, perovskite solar cells, and other similar technologies. Figure 5 illustrates the evolution of their efficiency over time. Notably, perovskite solar cells demonstrate significant potential in achieving high conversion efficiencies, both as standalone devices and when integrated in tandem with other types of cells.

Figure 5: Efficiency-levels of Emerging Solar Cells across Different Years

While there are multiple technologies that demonstrate efficiencies surpassing those of widely deployed crystalline silicon technologies, each of these technologies encounters obstacles such as the absence of established commercial manufacturing processes, limited reliability, high Levelised Cost of Electricity (LCOE), utilisation of expensive and scant materials, and other challenges. It is imperative to urgently establish facilities that expedite the commercialisation of promising technologies that are in advanced stages of research and development. Simultaneously, support should be extended to research and development centers focused on enhancing the reliability and lifespan of specific solar cell technologies like perovskite.

One route to achieve this is by leveraging the established International Solar Alliance, which currently comprises 93 member countries[2], a dedicated branch can be established to foster collaboration among various R&D centers. The primary objective of this branch would be to expedite the identification of viable technologies for commercialisation. Additionally, a separate forum can be established to provide guidance to solar PV manufacturing equipment producers, directing their attention towards these promising technologies for the establishment of giga factories or retrofitting existing ones. In addition, this approach will ensure that the solar PV manufacturing ecosystem, benefiting from the Performance Linked Incentive (PLI) scheme of the Government of India (GOI), stays abreast with technological developments and make course corrections as and when necessary. This will enable greater electricity generation from the same deployment area, solidifying solar PV technology as the cornerstone of electricity generation for India and for the world.

[1] https://www.nrel.gov/pv/cell-efficiency.html

[2] https://isolaralliance.org/membership/countries